ENGINE HEAD REPAIR SERVICE

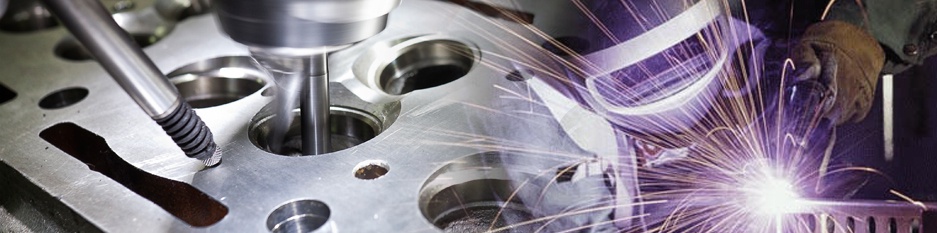

The complexity of the engine heads repair process causes that this department in our company is the most well-developed. The increasing quality requirements made us invest in the high-tech equipment for treating the combustion engine heads, produced by such companies as NEWEN or BERCO. Modern machinery stock and employees‘ experience enable us to do even the most complicated tasks at every stage of the repair.

Overall dimensions and type of damage are not a problem for us, therefore we repair the engine heads for every type of passenger cars, delivery vans, trucks, construction machines and even ships. Since we render also specialist welding services, we weld the engine heads made out of cast iron and aluminium successfully.

SPECIALIST WELDING

We carry out welding services for all types of materials such as cast iron, aluminium, tool steels, acid resistant steel, heat resistant steel and others. We render also the padding services with spray-up method for wide range of alloys and other materials.

We specialise in welding the iron casting of every overall dimensions. Thanks to the cast iron welding unique technology developed by us we weld machine bodies, engine blocks, collectors etc.

REGENERATION OF DISTRIBUTION SHAFTS

While using the technological knowledge potential, long experience related to pad welding of cast iron and cast steel as well as the machining possibilities in the range of polishing, we provide services connected with regeneration of distribution shafts on cams and pins for every type of combustion engines with the length not exceeding 3700 mm.

For repairing the distribution shafts, we use various welding techniques such as Tig and Mig/Mag welding and hot and cold thermal spraying. Since some producers are very demanding as far as their products are concerned, individual technologies for each type of shaft have been developed and their purpose is to obtain proper hardness and surface roughness. Relative to OEM requirements, we receive the hardness from 45 to 60 HRC on the cam and pin surfaces. The cam machining is conducted with copying method on the high standard polishing machine.

We give 12-month warranty for regenerated cams and pins.